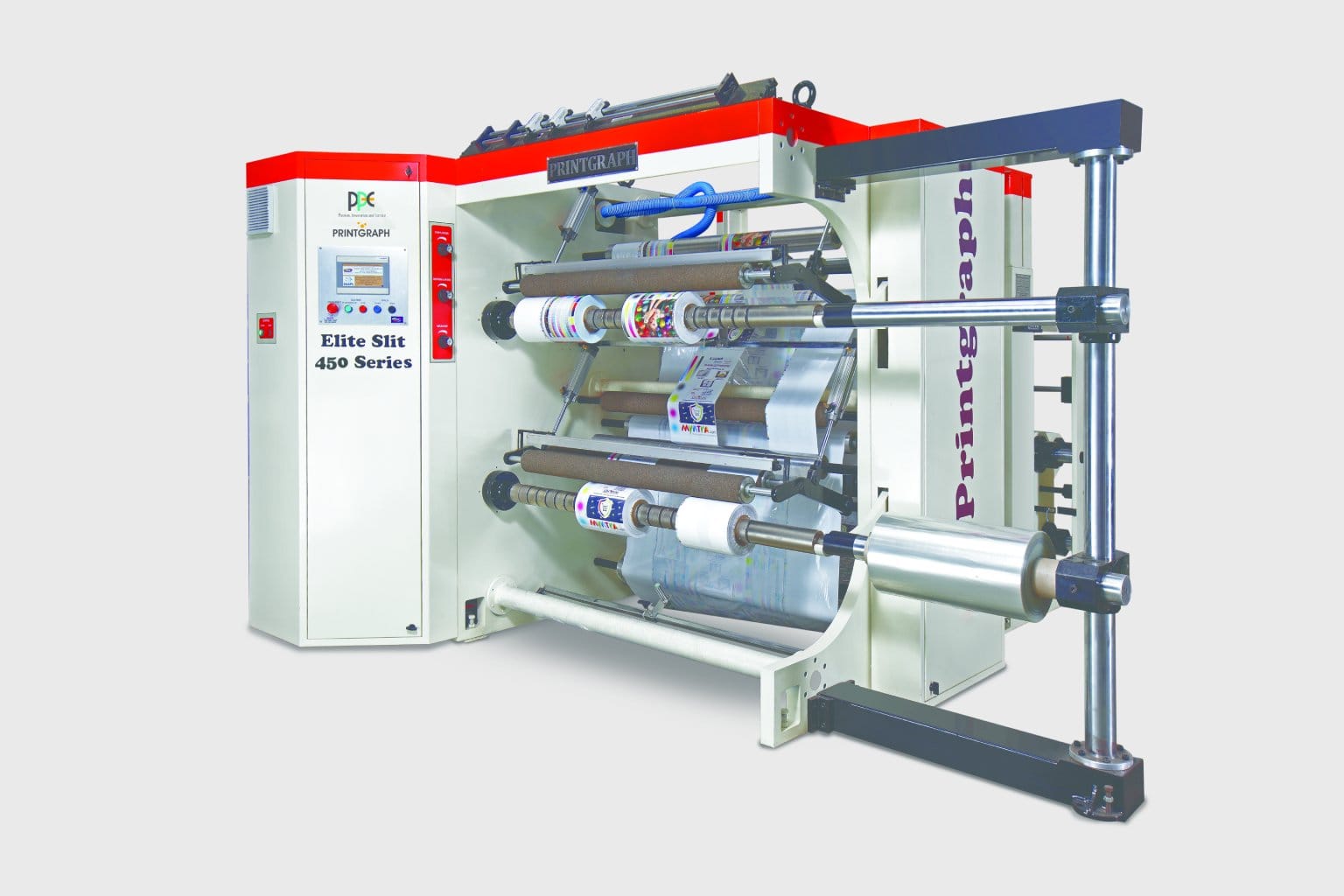

| Maximum Slitting Speed (Mtrs/Min) | 450 Mtr/min |

| Minimum Web Width | 800 MM |

| Maximum Web Width | 1600 MM |

| Slitting | 1500 MM |

| Min. Slitting Width | 50 MM (20 MM on request) |

| Core ID Unwind | 76 MM and 152 MM |

| Type of Unwind | Shaftless |

| Type of Rewind | Duplex with Cantilevered Fix Type Differential Shaft |

| Unwind Weight | 800 KGS |

| Unwind Diameter | 1200 MM |

| Rewind Weight | 100 KGS |

| Rewind Diameter | 600 MM |

| Substrate | PET: 10 – 25 mic. |

| CPP/BOPP/OPP: 12 – 50 mic. | |

| Films Made from PE: 30 – 100 mic. | |

| Film Laminates: 30 – 120 mic. |

At PPE we manufacture operator and operation friendly Slitting and Rewinding Machines for the flexible packaging and paper industry Often overlooked it is one of the most critical operations in the converting industry.

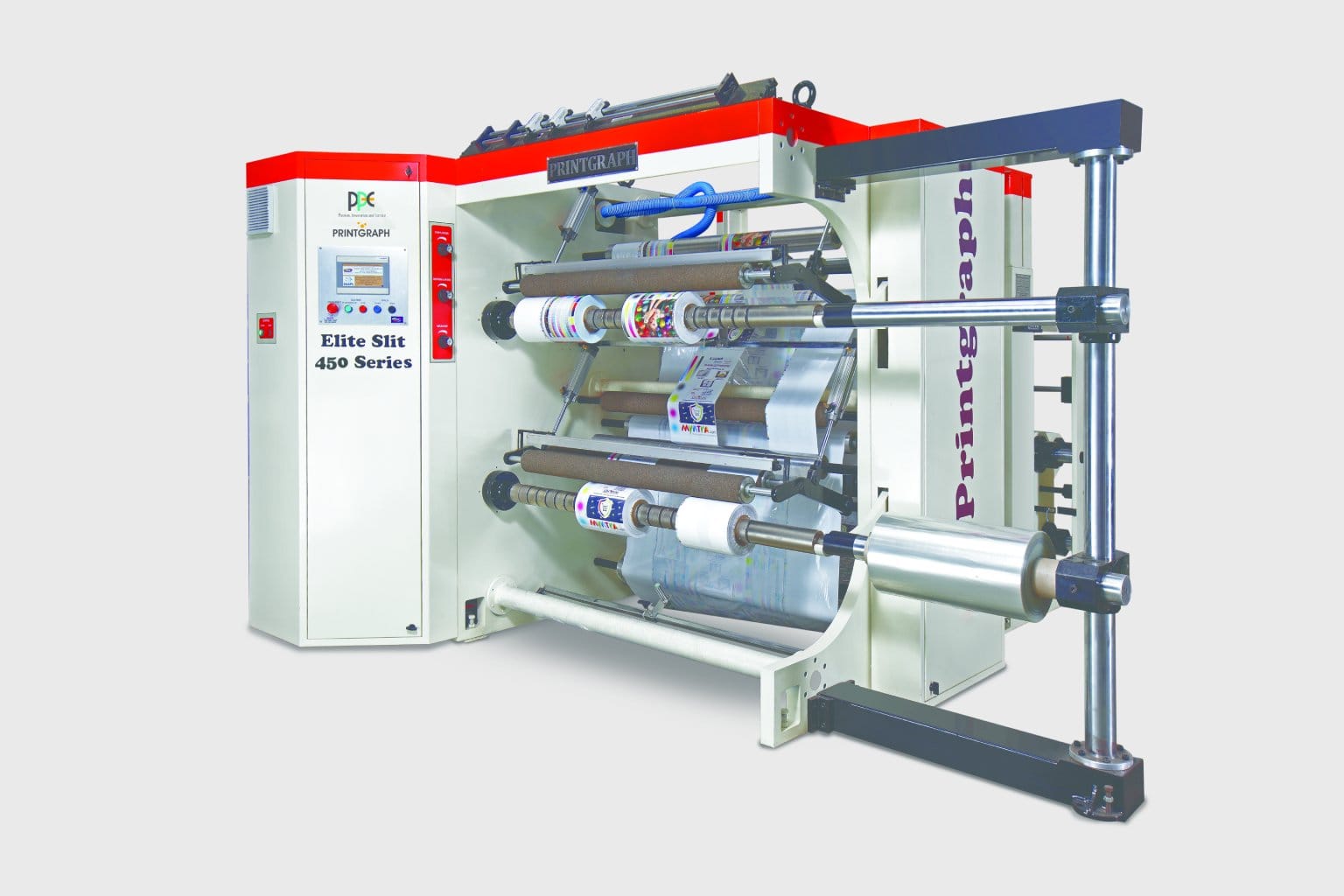

At PPE we manufacture operator and operation friendly Slitting and Rewinding Machines for the flexible packaging and paper industry Often overlooked it is one of the most critical operations in the converting industry.

| Maximum Slitting Speed (Mtrs/Min) | 450 Mtr/min |

| Minimum Web Width | 800 MM |

| Maximum Web Width | 1600 MM |

| Slitting | 1500 MM |

| Min. Slitting Width | 50 MM (20 MM on request) |

| Core ID Unwind | 76 MM and 152 MM |

| Type of Unwind | Shaftless |

| Type of Rewind | Duplex with Cantilevered Fix Type Differential Shaft |

| Unwind Weight | 800 KGS |

| Unwind Diameter | 1200 MM |

| Rewind Weight | 100 KGS |

| Rewind Diameter | 600 MM |

| Substrate | PET: 10 – 25 mic. |

| CPP/BOPP/OPP: 12 – 50 mic. | |

| Films Made from PE: 30 – 100 mic. | |

| Film Laminates: 30 – 120 mic. |

Social Chat is free, download and try it now here!